Pharmaceutical manufacturing carries strict requirements and high costs, creating a unique set of challenges for every production line.

Pharmaceutical lines move fast and demand perfect consistency. A single defect in tablet coating, blister sealing, vial filling, or capping can stop a line, create costly scrap, and disrupt compliance. Our high-speed industrial cameras give your team the ability to see exactly what happened on the line in real time and in replay. You capture the root cause of variations that ordinary vision systems miss, even when they occur in a fraction of a second. This provides the clarity needed to improve quality, reduce downtime, and protect your production output.

Designed for Tablet, Packaging, and Fill-Finish Lines

Every pharmaceutical process has its own challenges. Coated tablets may chip or delaminate before entering packaging. Blister packs can show micro leaks or misfeeds that are invisible at full speed. Vial and syringe lines often experience occasional fill spikes, stopper misalignment, or crimp issues. Our camera systems are engineered to capture these events in detail, in the middle of fast motion, inside clean room environments, and across your most sensitive areas of production. This gives manufacturing and QA teams an objective record that helps solve problems quickly.

Powerful Tools for GMP-Focused Operations

The pharmaceutical industry relies on traceability, documentation, and repeatable processes. Our systems support these needs with reliable high-speed recording, buffering, and replay tools that fit directly into everyday GMP workflows. Engineers and technicians can capture video around a fault, slow it down frame by frame, and identify the exact moment where something started to drift. You can validate fixes, train operators, and document improvements with confidence. With our portable and enterprise-level systems, you can place high-speed visibility exactly where your operation needs it most.

20/20 Hindsight puts high-speed industrial monitoring and troubleshooting in the palm of your hand with our smartphone app. Contact us for your custom solution.

A Proven Solution for Reducing Downtime and Scrap

Pharmaceutical manufacturers use 20/20 Hindsight systems to eliminate recurring line stops, uncover subtle machine timing issues and verify equipment changes. Whether you are troubleshooting a coating drum, inspecting blister seals or monitoring a high-speed syringe line, our cameras provide a clear visual record that supports faster problem resolution. Teams often discover that just a few captured events can save days of trial and error. The result is stronger process control, improved throughput and higher confidence in every batch that leaves the facility.

More Than Just High-Speed Video

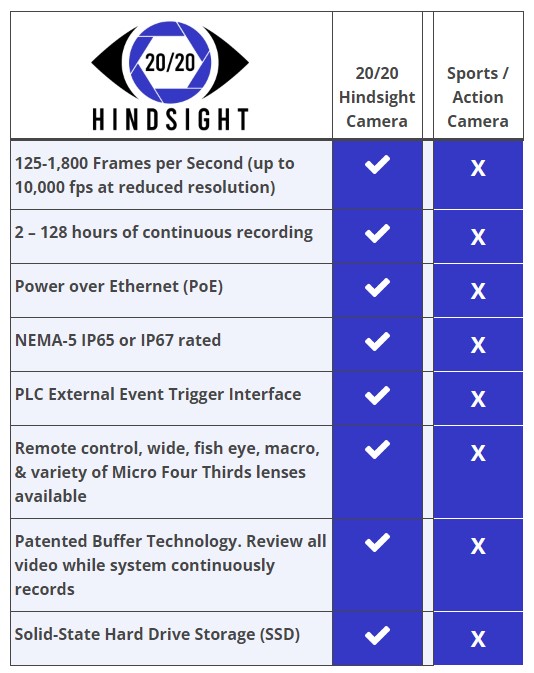

What sets 20/20 Hindsight cameras apart? Our customers appreciate the vast recording buffer, user-friendly software, and the ability to deploy the system in almost any environment with minimal setup or configuration needed.

Complete Troubleshooting Systems

Learn what makes our industrial-strength solutions ready for any environment. From portable to enterprise, 20/20 Hindsight industrial troubleshooting camera systems can meet your need and budget.

Camera Technology

Learn what makes our custom-designed cameras built for any condition. From wet to dry, from sterile to the most brutal production environments, our technology is built to handle it all.

Software Technology

From Windows desktops, laptops, and all mobile platforms including Android and iOS, we have software and apps to cover every need and make it all work together on your existing hardware.