Whether you are troubleshooting a filler infeed, verifying a seamer setup, or tracking down a case packer jam that appears every two hours, these problems are common across fast beverage lines.

Beverage manufacturing lines are among the fastest in the world—filler runs, seamer setups, case-packers, and pack-out operations often exceed thousands of units per minute. At those speeds, you can’t afford to guess what caused the jam or defect. Our high-speed industrial camera systems let you see exactly what happened, in slow motion and in full clarity, without slowing the line. With real-time buffering and advanced playback, you gain precise visibility into problems on your beverage line.

Built for Liquid Handling, Filling, Seaming, and Packaging

From high-speed liquid fillers, capper spindles, labeling machines, and case packers to secondary packaging and palletizing, beverage operations demand systems that withstand moisture, condensation, and constant motion. Our cameras are designed specifically to perform in these harsh production environments—wet floors, rapid motion, conveyor transfers, splashing fill spouts—so you can capture root-cause data when it matters most.

20/20 Hindsight puts high-speed industrial monitoring and troubleshooting in the palm of your hand with our smartphone app. Contact us for your custom solution.

Key Beverage Line Use Cases

- Detecting splash, foam or fill-level error in high-speed liquid fillers

- Monitoring capping torque or alignment on wet bottle conveyors

- Troubleshooting seamer mis-setups on aluminum cans or PET bottles

- Capturing jams or misfeeds on case packers and end-of-line wrap machines

- Verifying label placement, shrink-sleeve application, and closure integrity

Tools That Drive Quality and Operational Efficiency

In beverage production, the margin for error is razor-thin, and downtime is costly. Our high-speed video systems provide not just footage, but actionable insights: frame-by-frame review, instant sharing of clips, portable deployment when you need the camera on a different line, and mobile-app integration so your engineers can respond even when they’re on the go. Combine that with industrial-rated hardware – IP-rated enclosures, rugged mounting, long-duration buffers – and you get a solution built for persistent production environments.

Proven Results in Beverage Packaging & Processing

Beverage manufacturers rely on 20/20 Hindsight to reduce jam-related downtime, eliminate recurring fill anomalies, and improve line throughput. By capturing high-speed events and isolating root-cause motion, teams can resolve issues faster, validate machine setups, and drive continuous improvement in packaging performance. The result: fewer interruptions, lower scrap rates, and stronger confidence that each case leaving the line is packaged right.

More Than Just High-Speed Video

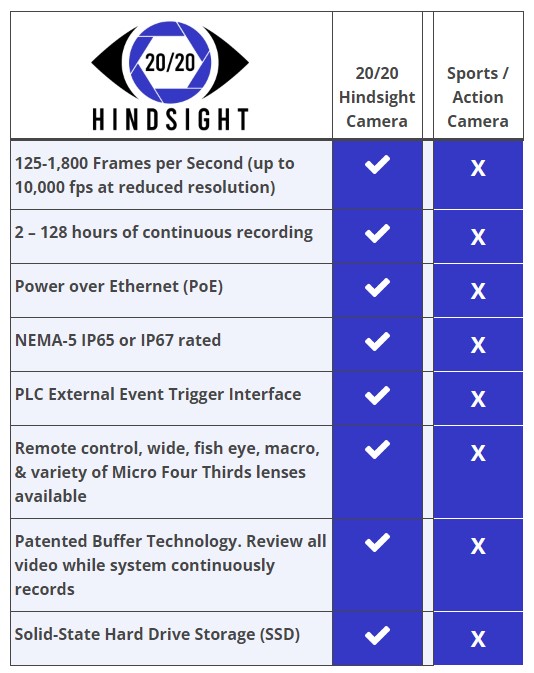

What sets 20/20 Hindsight cameras apart? Our customers appreciate the vast recording buffer, user-friendly software, and the ability to deploy the system in almost any environment with minimal setup or configuration needed.

Complete Troubleshooting Systems

Learn what makes our industrial-strength solutions ready for any environment. From portable to enterprise, 20/20 Hindsight industrial troubleshooting camera systems can meet your need and budget.

Camera Technology

Learn what makes our custom-designed cameras built for any condition. From wet to dry, from sterile to the most brutal production environments, our technology is built to handle it all.

Software Technology

From Windows desktops, laptops, and all mobile platforms including Android and iOS, we have software and apps to cover every need and make it all work together on your existing hardware.